3D Printing Technology and Construction: Creating New Frontiers in Building Technology

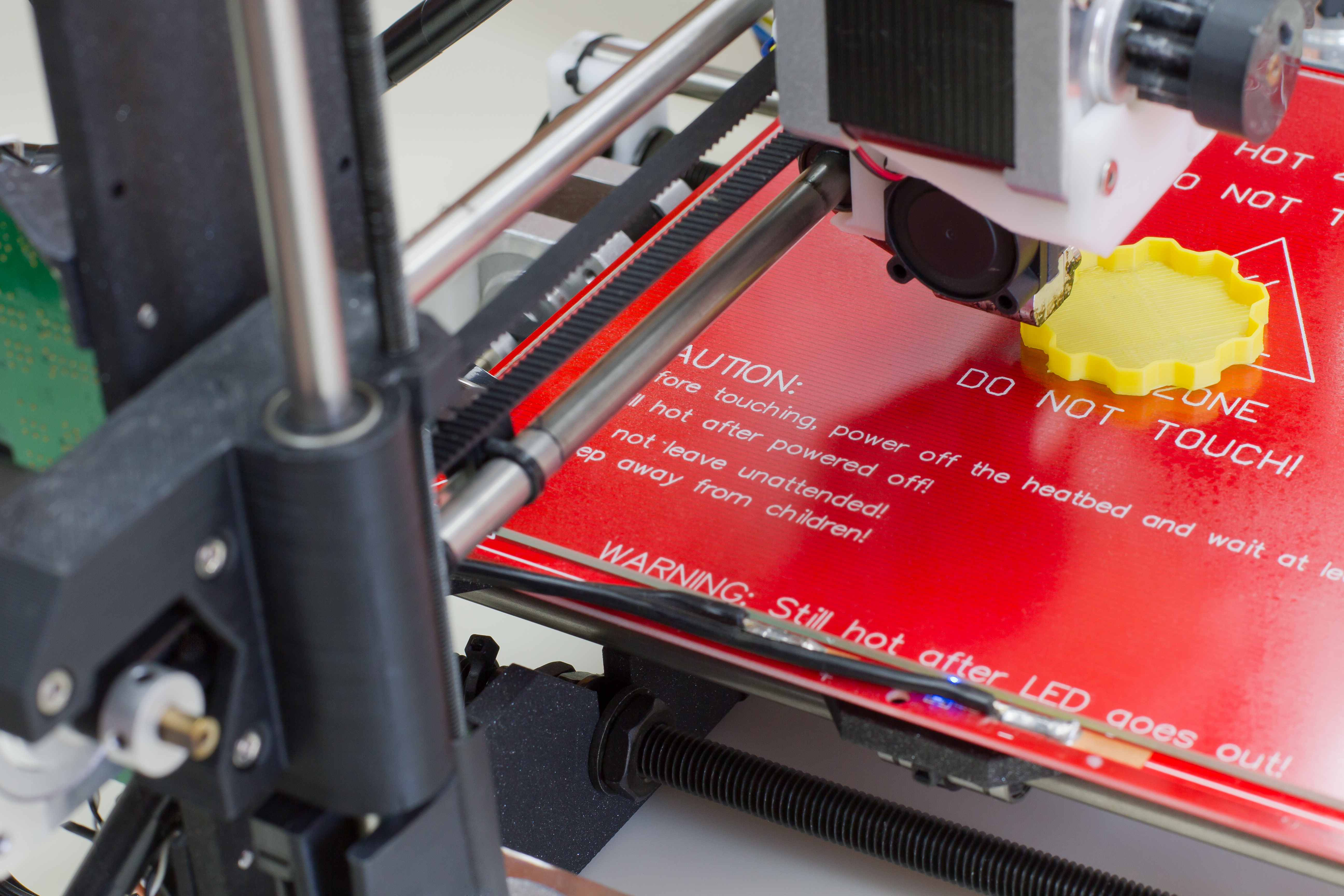

Recently, 3D printing technology has been able to create many unusual devices such as limb replacements, medical devices, and three-dimensional items such as light fixtures or iPad stands. 3D printing has been embraced by several innovative industries already, is construction next?

3D Printing Technology and Construction: Creating New Frontiers in Building Technology

Previously, those in the construction industry interested in harnessing the power of 3D printing technology were hampered by scale. 3D printers typically work in a small space to print projects that fit into the printer’s small box. With the development of free-standing 3D printers, larger projects are becoming a reality.

This summer, a Chinese 3D printing company printed an entire house. ZhouDa Group’s printing project may make construction difficulties a problem of the past. Chinese contractors typically utilize bricks or reinforced concrete to build homes. Since concrete cannot cure in wet weather, rainy days create major scheduling delays. By printing the structure in the lab and assembling on site, the home was produced faster than any traditional method possible. From printing to assembling, the entire structure was completed in a single week with assembly taking only three hours on-site. The home is earthquake and termite proof, as well as fire and flood resistant.

As 3D printing techniques advance, the materials they use become more advanced and present new opportunity. Typical metal 3D printers use laser sintering which uses a high-powered laser to fuse layers of metallic powder together, layer by layer. New technology that uses robotic arms fitted with specialized welding heads allows designers to create metal structures essentially one drop of metal weld at a time. The arms build the structure additively drop by drop and drawing out longer rods of steel. A Dutch company is working to build an intricately detailed bridge as a trial project.

Implications of 3D Printing for Green Building Design

With the construction industry’s focus on cost-saving designs that are also environmentally sound, 3D printing may open the door for revolutionary building techniques to become commonplace. Future buildings may be constructed with 3D printed matrices for a building’s walls that are then outfitted with traditional construction materials such as concrete exteriors and drywalled interiors. The result would be a building that looks like any other from the outside but ultimately would be less expensive to construct without sacrificing strength. 3D printing can create walls that are stronger than those constructed by wood and comparable to those comprised of concrete yet they use less material and waste far fewer resources.

With over 37 years experience, South Bay Construction is an industry leader in Northern California construction. We employ cutting-edge construction methods to add value at every stage of the construction process. From pre-construction through the final stages of the project, we are your trusted partner in the construction industry.